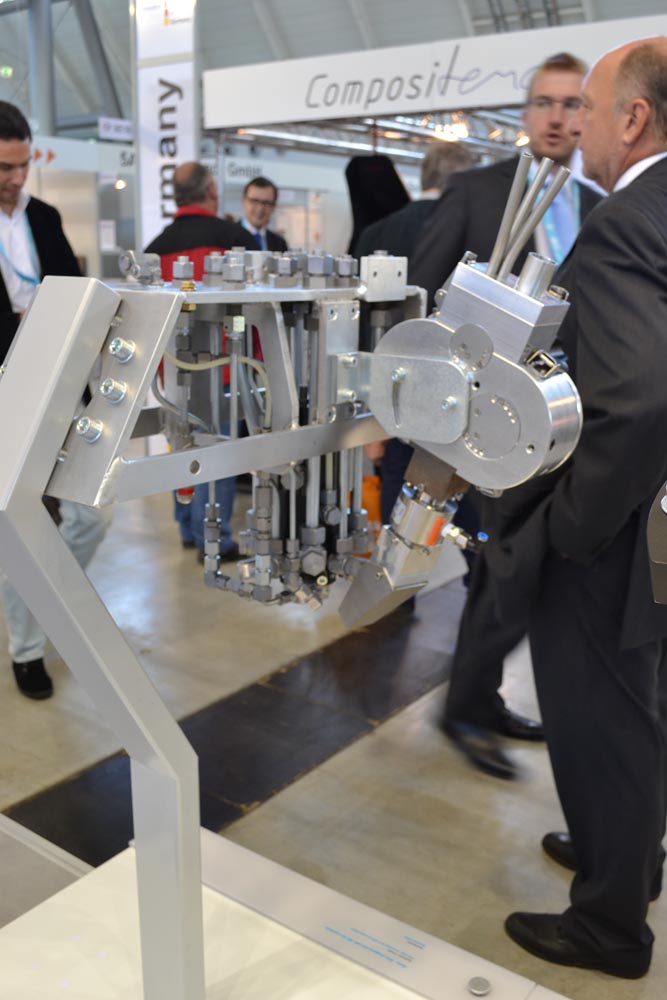

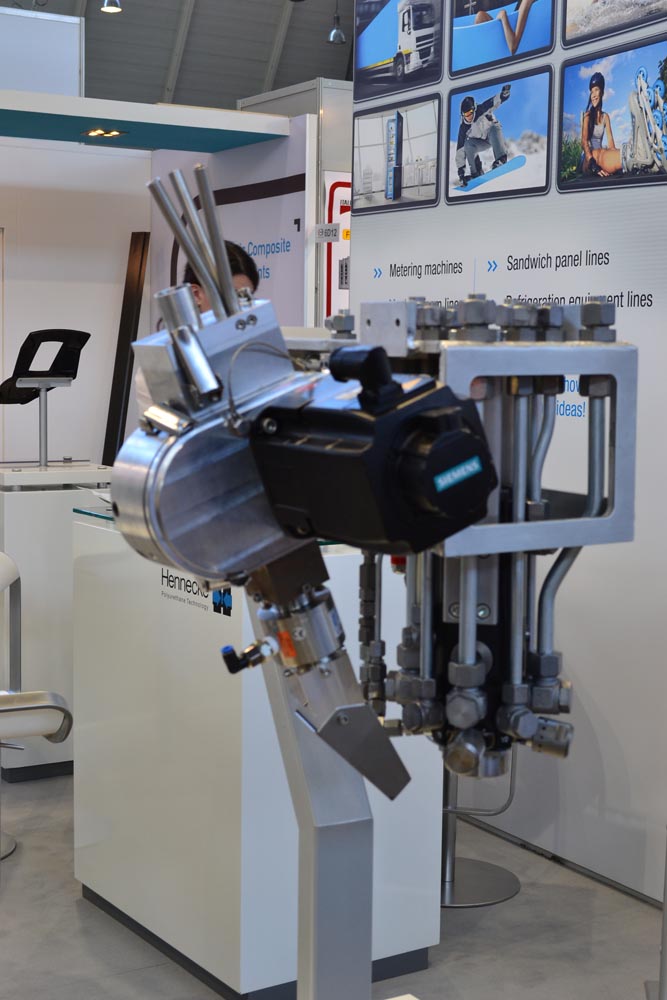

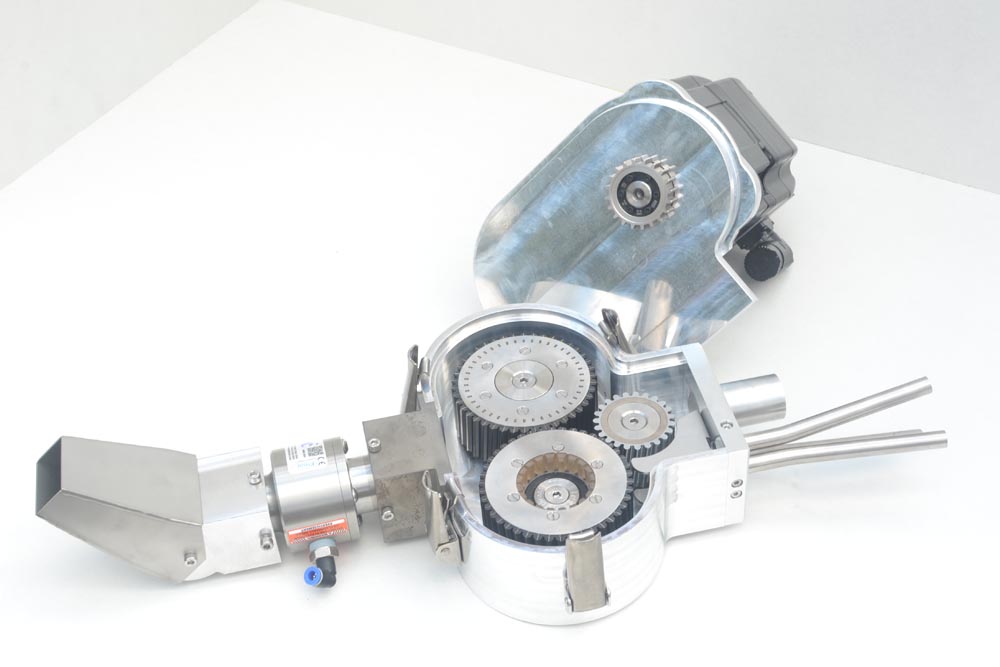

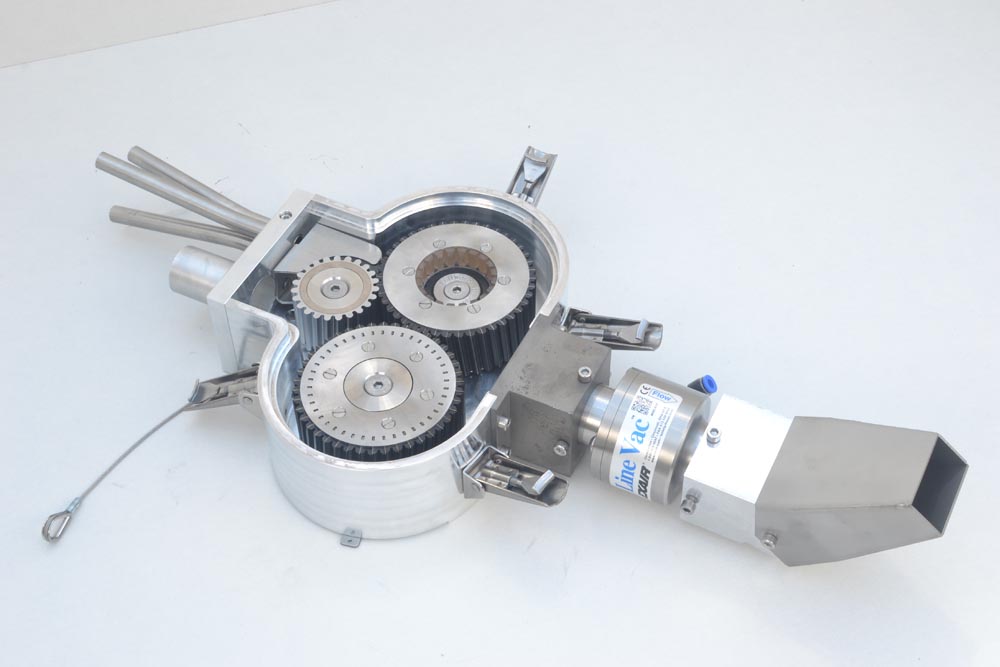

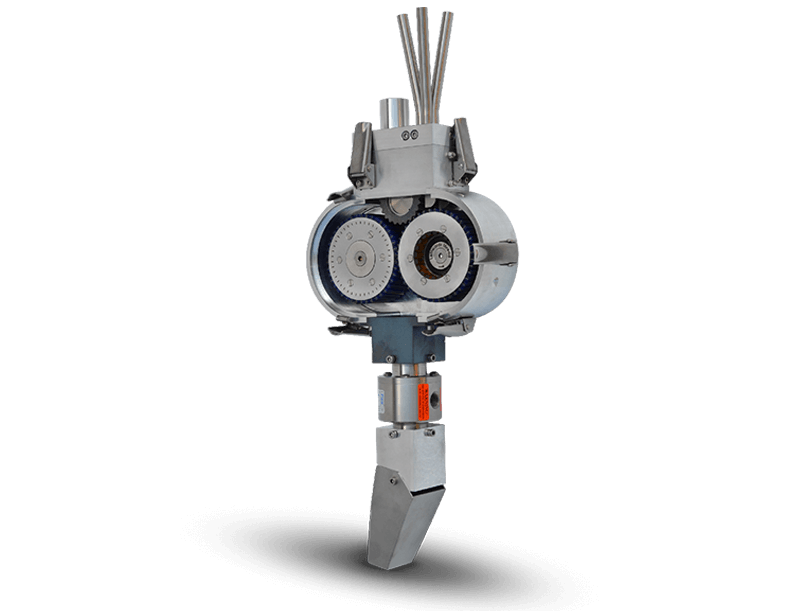

The PRM is based on the tOOchop® technology and is more durable and economic than the T-serie. It has a special air flush system and layup system for robot application. Enable to run without absolutely no disturbance, do high volume (Kg/h) and cut multiple fibers strands.

This machine is suitable for

Fiber

Glass (assembled roving)

Market

Automotive & Aerospace, Raw materials, Consumer products

Capacity

Mid-range

If you would like to have more information about this machine, please press the button below. We will ask you to fill out some details about yourself, after which you will get the link to the specification sheet.