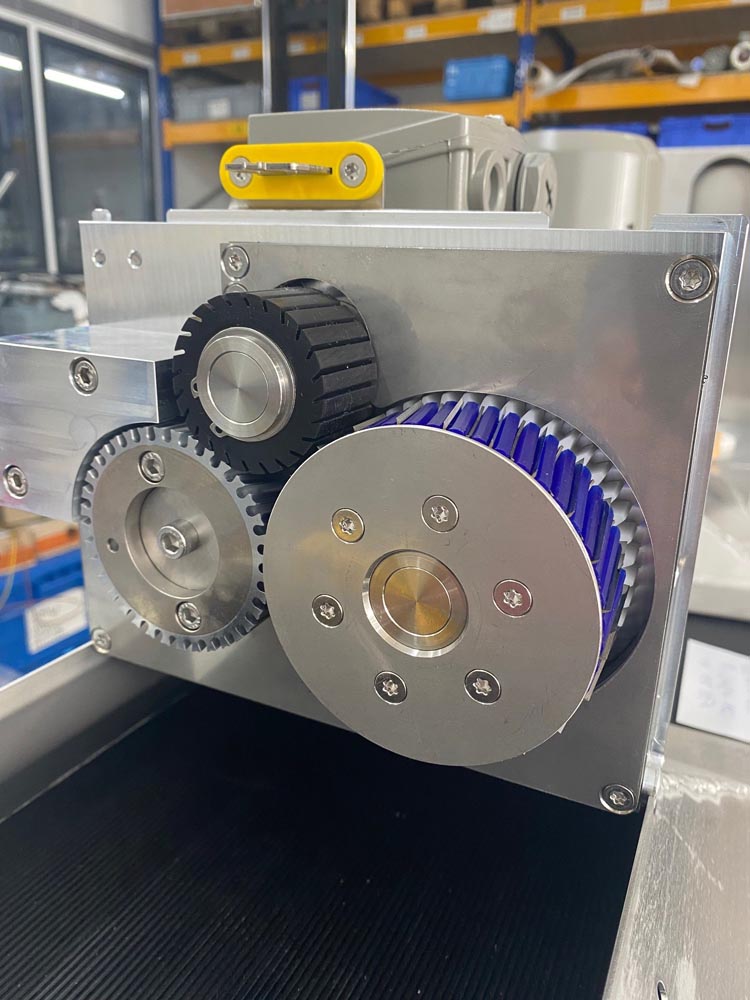

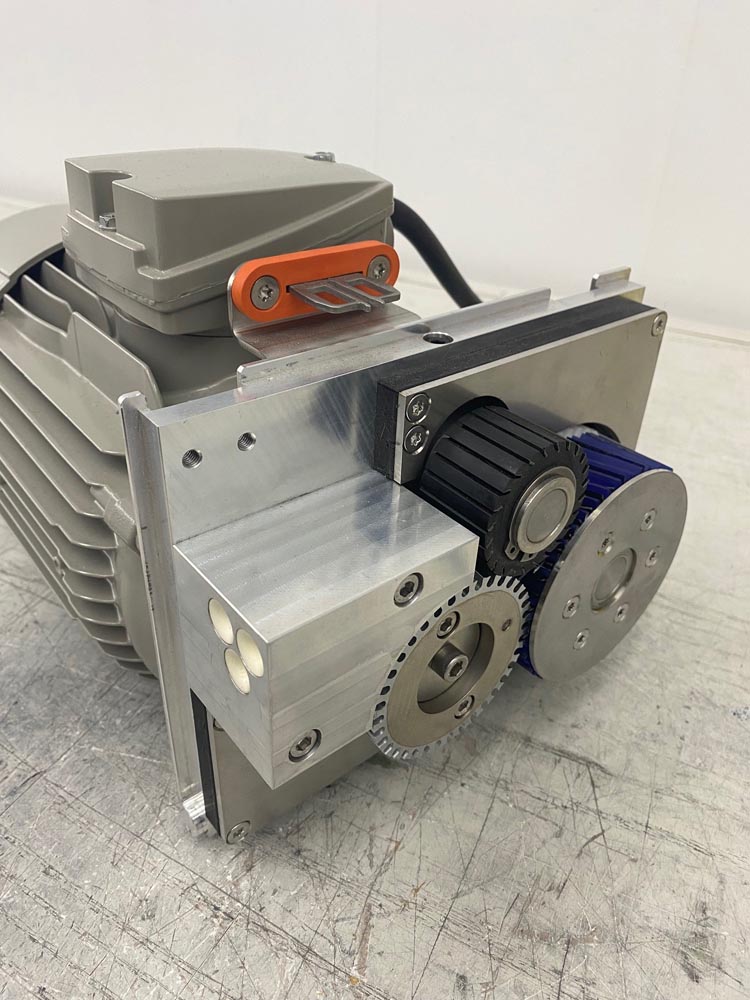

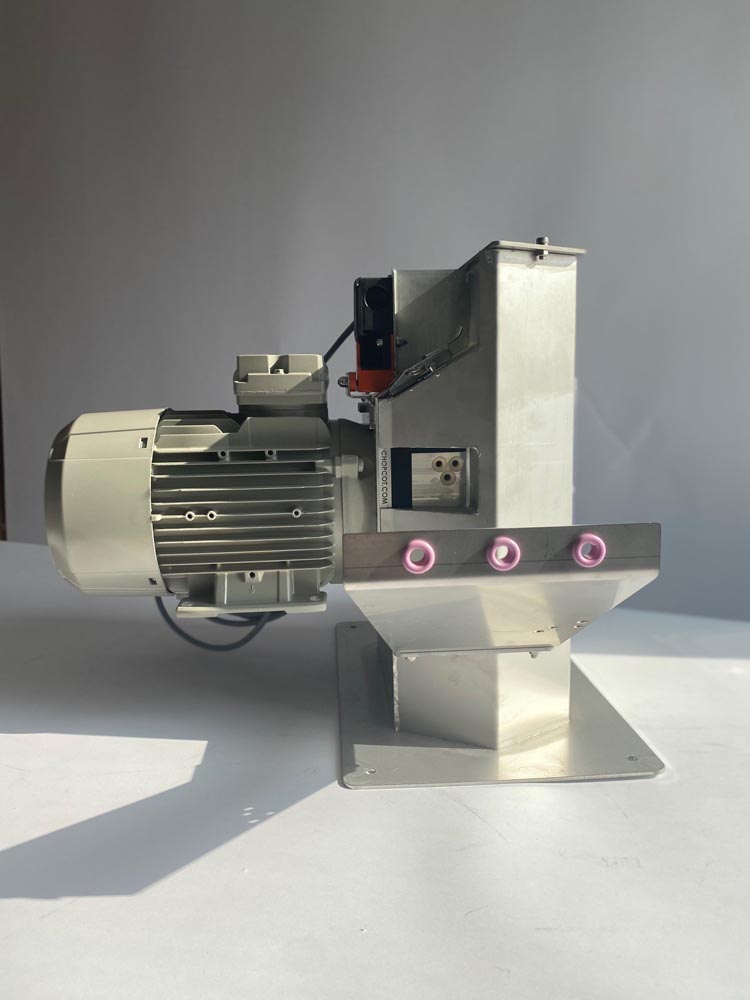

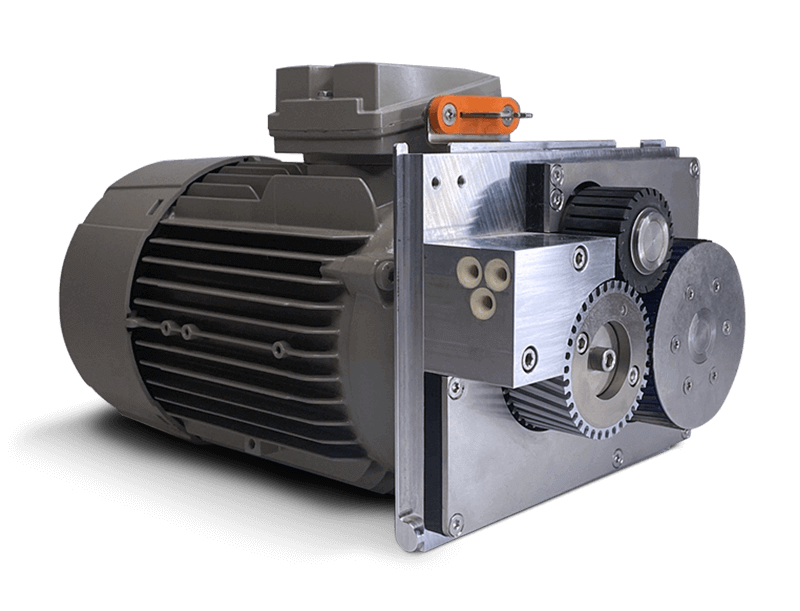

One of the first technologies we introduced is the Chopcot®. This chopper is still the absolute number 1 in various markets when it comes to reliability and economics. It is suitable to cut multiple types of breakable fibers. Furthermore this chopper is suitable for use in different setups (horizontal and vertical) and there is also a version for robot applications.

This machine is suitable for

Fiber

Glass (assembled roving), Silica, Quartz, Carbon, Basalt, Natural (correct sizing)

Market

Automotive & Aerospace, Raw materials, Consumer products

Capacity

Low & Mid-range

If you would like to have more information about this machine, please press the button below. We will ask you to fill out some details about yourself, after which you will get the link to the specification sheet.