Fiber cutters for all sorts of Fiber

We are able to chop a wide variety of fibers. Pick your fiber and find our Solution.

Polymers

Polymers

- Polysteel

- Aramid (Kevlar)

- UHMWPE (Dyneema)

- Polyester

- Nylon

- Acrylic

Natural

Natural

- Flax

- Jute

- Kenaf

- Sisal

- Cotton

Steel

Steel

- Aluminium fiber

- Stainless steel wire

- Steel wire

Glass

Glass

- Fiberglass

- Quartz

- Silica

Carbon & Basalt

Carbon & Basalt

- Carbon fibers

- Basalt fibers

What makes our solutions Unique

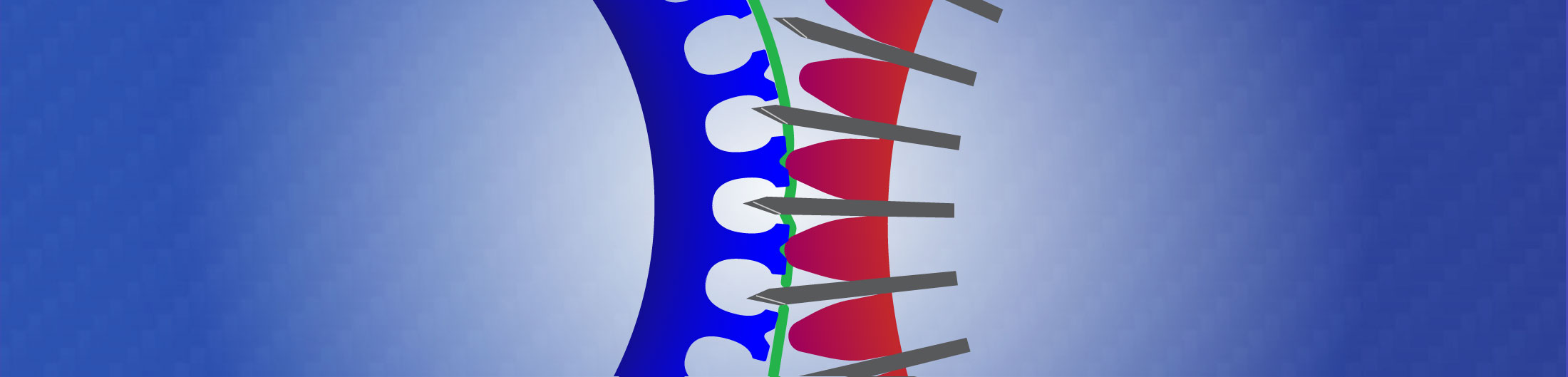

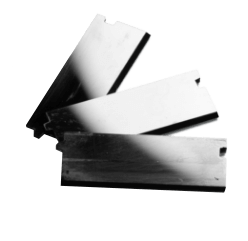

Cutting in the air

Unique and patented chopping technology

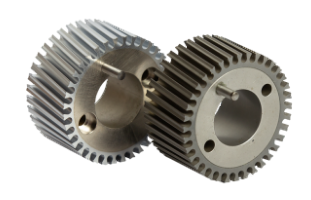

Reliable & durable solutions (> 10 years)

Highest quality & accuracy of the strands

Refined and customizable solutions

No product contamination

Plug-and-Play

Proud of all our Customers and Accomplishments

No 1

Position in various markets

250+

Customers

30+

Solutions

73

Countries

25+

Years of experience

15+

Patents

Why van der Mast

Business

Van der Mast Innovations, founded by Mr. WF van der Mast, began over 25 years ago with a patented solution for glass fiber production challenges. Today, we offer 30 chopper solutions to 250 customers in 100 countries. Ongoing research brings new innovations in 2025. Stay tuned!

Team

Our team develops innovative solutions for cutting various materials used in products like cars, airplanes, and helmets. We operate globally, often collaborating with clients and institutes, and are regularly looking for new team members. Check out our vacancies and opportunities!

Innovation

We believe today’s innovation shapes tomorrow’s success. By focusing on customer needs and trends, we develop sustainable solutions, like blade resharpening, reducing CO2 footprints and TCO. We invest in long-term partnerships for environmental and business benefits.

Our sustainability Commitments

Our goal is to develop & produce choppers with the right balance

between a long lifespan, maximum safety and the lowest possible impact on the Environment.

Re.duce

Reducing our environmental footprint is for example possible by using more wear-resistant or tougher raw materials for our ribs. Furthermore we established a longer life span by designing other shapes of the ribs as well as developing unique chopping technology for significantly less wear of all parts.

Re.use

The main parts of our solution are the different rolls. Technically these rolls can last indefinitely if you replace the coating every now and then. We have found an environmental way to release the coating. After which the rolls can be checked, adjustments can be made and renewed with a new coating. After which they take on a new challenge.

Re.cycle

We have done research to enable the possibility for our customers to return their used parts. Which led to a succes. With it case-by-case carefully checking if for example resharping the blades is a possibility we are able to expand the lifetime of the blades significantly (3 to 4 times) and thereby lower the TCO for our customers as well.

Let’s stay in Touch!